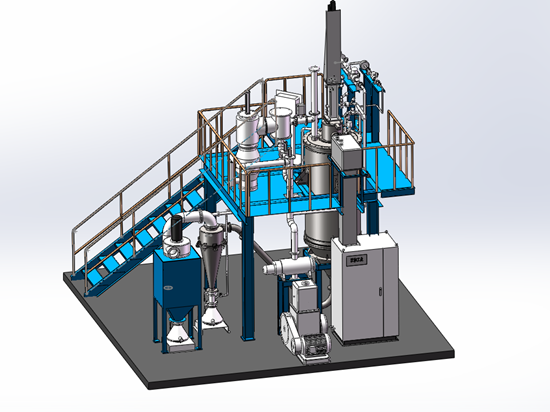

EIGA System for Producing Titanium Powders

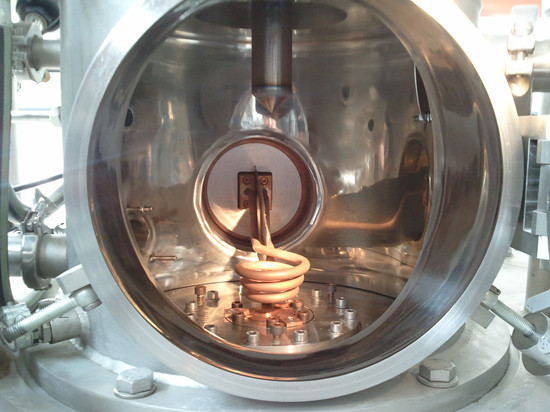

Working principle: Melt the pre-made Titanium alloy rods under proper vacuum conditions. The liquid metal flows down and passes the nozzle. High pressure air flow goes through the tight coupling nozzle and then cracks and atomizes the liquid metal into a large number of tiny liquid drops. These tiny liquid drops will solidify during flying. The mixture of powders and air will be sent to the cyclone separator via the convener pipe. And the rough powders and fine powders as well as atomizing gas will be separated in the separator. The metal powders will be collected in the sealed container.

Metal powder gas atomization technology is mainly used for metal powder production of high grade and high-tech requirements. Main technical indicators of inert gas atomized powders are as following: high degree of sphericity, high purity, low oxygen, rapid solidification, homogeneous micro-structure etc.

Main technical parameters

l Rated capacity: 10KG(in terms of steel)

l Powder material: Spherical Titanium alloy powder

l Particle size: 10-150um

l Atomization ratio: 75%

l Oxygen content ≤ 300ppm

l Melting temperature:1700℃

l Rated power: 300KW

l Rated frequency: 300Hz

l Limiting vacuum: 6.67×10-1Pa

l Working vacuum: 1-3Pa

l Pressure rising rate ≤5pa/h

l Input voltage:3N 380V

l Working pressure: 2-10Mpa

l Air flow:600-800 m3/h(the user is responsible for liquid Nitrogen gasification and pressure machine)

l Protective gas: 4N Nitrogen or Argon

l Titanium bar specification: φ60×800mm(as TC4 density, the bar weighs 10kg)

|  |

Service Hotline

0731-22335988