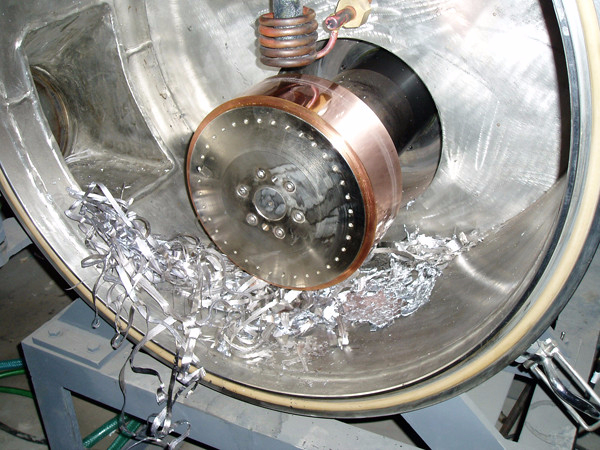

Vacuum Melt Spun Furnace for NdFeB Ribbon/Flakes

Brief Description

Qualified formula metal alloy ingot raw resource under vacuum and inert atmosphere to melt, refine and spray, quick cool, primary crush, thus make metal mini-type magnetic sheet for continuous vacuum spinning equipment.

Core equipment for bonded magnet sheet, mainly used for intermediate products of magnetic powder 13-9, 14-12, 15-7, 16-10

Design capacity: 2t/24Hrs, with 3.5t/24Hrs limitation

Main Technical Parameters

1) Melting material: NdFeB alloy ingot

2) Flow rate: standard for 1.5kg/min. Limitation for 2.5kg/min

3) Melting temperature: general at 1350℃, limitation: 1500℃

4) Melting system: IGBT power, melting power is over 250kw, about 40minutes from power on to totally melt. (calculating by melting 100kg pure iron)

5) Vacuum system

-Ultimate vacuum≤1mTorr (empty furnace fully degassing)

-Working vacuum(hearth):10mTorr, 2mtorr in vacuum, 50mtorr in Ar

-Rate of pressure raise:≤5mTorr/min(empty furnace fully degassing)

-Time for gas exhaust(melt-spinning cabin), about 30 seconds from atmospheric pressure to 80mTorr(measured after empty furnace fully degassing )

-Connector with leak detector;main vacuum gas exhaust tube with dust filter system.

6) Secondary system

Can load 50kg ingot with diameter below 200mm

7) Cooling system

Cooling chamber has vibration cooling function which can cool temperature from 700℃ to 60℃within 2 minutes;

Cooling chamber is directly connected with melt-spinning chamber.

Service Hotline

0731-22335988